![]() A key service we provide is to work with you to develop the specifications for the parts you need. Our engineers will help select the most appropriate materials for the parts’ function, as well as the best production methods for the quantity you require in order to minimize costs, improve the parts’ durability and keep your maintenance costs down. Our strength is built on thirty years of experience in seal design and engineering.

A key service we provide is to work with you to develop the specifications for the parts you need. Our engineers will help select the most appropriate materials for the parts’ function, as well as the best production methods for the quantity you require in order to minimize costs, improve the parts’ durability and keep your maintenance costs down. Our strength is built on thirty years of experience in seal design and engineering.

We design a wide range of elastomer parts in different colors, grades and hardnesses (elastomers that comply with FDA and 3-A food standards, with aeronautical norms 20A&B, 31B, 41B, 50D, 61D and with drinking water standards, ACS, WRAS, SDWA, etc.). We can identify your parts with your company’s reference codes, logo or come up with your own color-coded system your marketing department will appreciate.

Our elastomer molding shop produces a range of O-ring options:

Our elastomer molding shop produces a range of O-ring options:

- Custom-made (non-standard sizes)

- Standard sizes but with special elastomers

- Of hardnesses varying from 25 ShA to 97 ShA

- In all colors

- Supplied with various certificates, control documentation and/or individually packaged

- Compliant with specific sanitary/technical norms (FDA, 3A, ACS, SDWA), with aeronautical industry standards and with USP Class VI certification for medical components, etc.The molding tools for all our elastomer parts are made in our own machine shop.

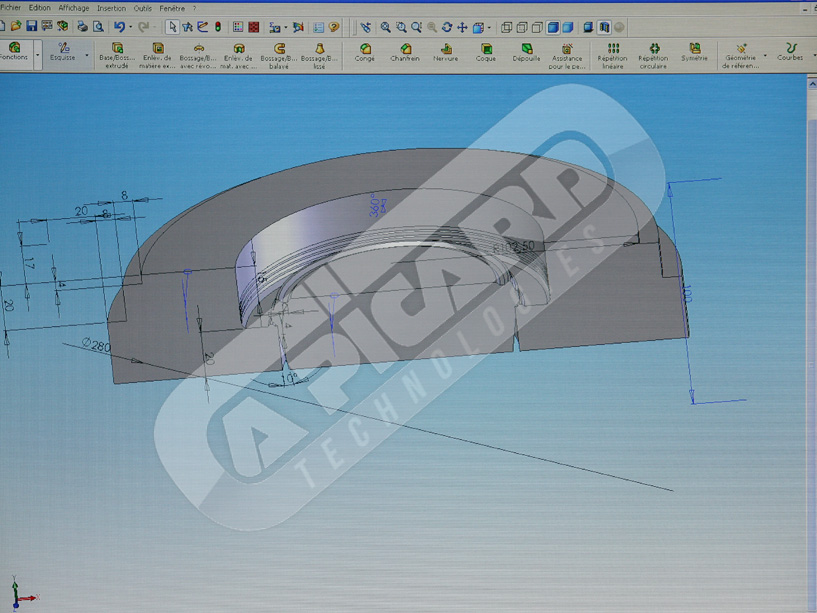

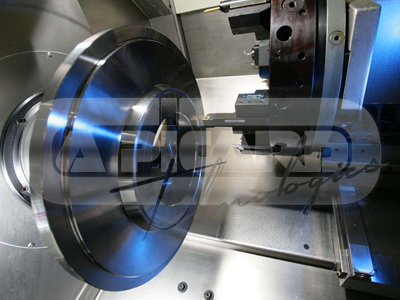

Our multiaxis machines are capable of producing the most complex molds.

Producing our own molding tools on site gives us an important edge: we have a fast turnaround time, offer a very competitive price advantage, and can eliminate intermediary costs, transportation costs and additional costs for modifying molds.

See also: Elastomix® - Elastomax®